Category

Plastic Waste Container Bin Mould

Ningguang Mould have more than 10 year experience in making plastic mould, injection mould, compression mould. It is a p

Basic Info.

| Model NO. | TXP906 |

| Application | Home Use |

| Runner | Cold Runner |

| Design Software | AutoCAD |

| Installation | Fixed |

| Certification | ISO |

| Standard | DME |

| Customized | Customized |

| Cooling | Extra Cooling Using Becu |

| Transport Package | Wooden Case |

| Specification | ISO9001: 2000 |

| Trademark | NINGGUANG |

| Origin | China |

| HS Code | 84804100 |

| Production Capacity | 20 Sets/Month |

Product Description

| Product Name | Plastic Waste Container bin Mould ( TXP906) |

| Cavity and core steel | 1.2738 (28-32HRC) |

| Slider/lifter/cams | 1.2344 (H13) |

| Cavity/imprint | 1 |

| Ejection system | Ejector pins, ejector plates driven by hydralic cylinders |

| injection system | Yudo hotrunner |

| Mold finish | Technical polishing grain 400 + chrome plating |

| Cooling | BeCu to help the cooling at botom and handle |

| IMC system | N/A |

| Cycle time | 1 minutes |

| Mold life | 500000 shots |

| Mold type | Serial mold |

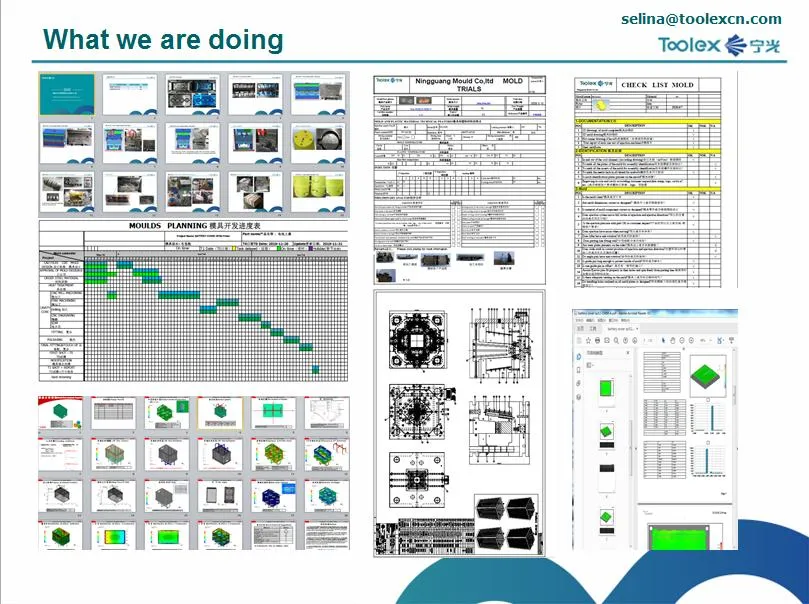

| Our Serive | MDF report / mold flow analysis |

| Weekly process report with photos | |

| Quality control team following project | |

| Trial report with video and free samples | |

| Sample and mould dimension report | |

| Optional service | bulk production |

| primer, top coating | |

| assembling & packing |

Ningguang Mould have more than 10 year experience in making plastic mould, injection mould, compression mould. It is a professional plastic mould factory in Huangyan, China. Our aim on international market, not only working for domestic market, we got to know what's the European mould quality standard and established our own design and manufacture standard.

Our customers come from domestic market and international market. Domestic market includes provinces like jiangsu, anhui, shenzhen, hebei and shanxi etc. International market contains USA, Canada, Spain, Finland, Poland, Pakistan, phillipines, Italy and Sri Lanka ertc.

Advantage:

1. Huge capacity

2. Ensure quick response to any problem.

3. Our equipments to serve the whole process from machining to inspection to mold trials., can provide mould progess photos every week.

4. Can provide steel certification, and heat treatment certification.

5. Can provide easy damaged spare parts for plastic mould/injection mould.

6. Very clean parting line and high quality polish skill.

Why customers choose our Ningguang Mould?

1. Design experience for many years

2. The strength of production capacity, can supply 200--300 sets per year and delivery on time

3. Good quality

4. Good cuminication skills and good service with customers, schedule are made

Weekly reports with detaild photos, sent to customers for monitoring

5. We are not only supply plastic mould, also supply rapid prototypes

6. Provide low-volume production for ensure mould quality before shipment

Plastic Mold Expertise:

1. Injection moulds for automotive(Auto Bumper mould, Auto Door mould, Auto Lamp mould...)

2...Plastic moulds for Home Appliances(washing machine mould, TV mould, air conditioner mould)

4. Plastic injection mold for electronic products

5. Plastic molding for household products(bucket mould. Basket mould, trash bin mould, chair mould...)

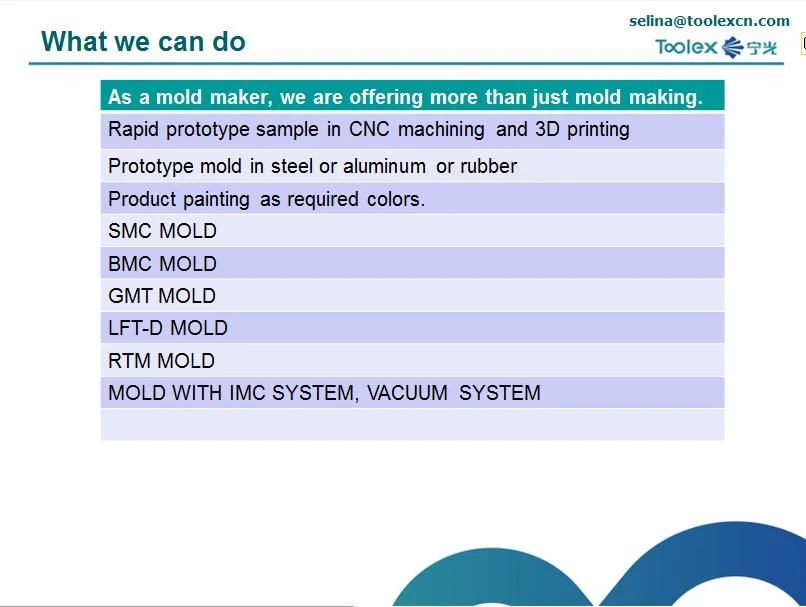

6. Compression mould(SMC mould, BMC mould, GMT mould)

Documents for Mold Shipment

1. Tool check-list.

2.. Steel certifications.

3. Steel dimensions report.

4. Mold tryout process sheet.

5. Tool assembly drawing printings.

6. Part drawing and latest dimensions report.

7. CD contains 2D & 3D mold drawing, electrode data and all above information.

If you have any new mould project, please sent your 2D/3D drawing or sample picture with whole of dimentions to us, we will reply your soon.