Category

Customized Injection Plastic Furniture Chair Table Stool Molds Making

Overview Customized injection plastic furniture chair table stool molds making We are offers customized plastic injectio

Overview

We are offers customized plastic injection moulds according to customers' requests . Mainly including household mould, housewares mould, commodity mould, plastic furniture mould, chair mould, table mould, stool mould, crate mould, dustbin mould, pallet mould, flowerpot mould, laundry basket mould, painting bucket mould, drawer mould, basket mould, baby toys mould, trash can mould, basin mould, bucket mould, spoon mould, knife mould, fork mould, disposable box mould, thinwall box mould, cap mould etc.

In the mold design of the plastic chair:1: We will fully analyze the chair according to the principles of injection molding (such as deformation, shrinkage, etc.).2: We will have serious and effective communication with mold buyers, including details such as weight, style design, size and appearance, stability and wear resistance of plastic chairs.3: We will refer to the previous chair injection mold design experience to improve the mold design.

View more plastic injection moulds,you can click pictures.

How to do Injection mould/mold order processing :1 Design: according to plastic samples/ 3d drawing,it is free .2 Discussion: mould metal,cavity number,runner,payment method.3 Design mould: we will send drawing to you, you can check and confirm.4 Mould machine tooling: we will send machine working photos every week.5 Mould testing: we will send mould testing video and samples to you.6 Shipping : after confirm samples,we will shipping molds.

PRC Mould always think more for clients , it is about saving time and money. We are looking forward to working with you.We provide good after-sales service, your satisfaction is our goal.We are not the biggest, but we are responsible and care about every mould quality for long-term business.Let us win to win together.Welcome to send us mould inquiry.

Basic Info.

| Model NO. | prc mould-new-0005 |

| Application | Household Appliances, Furniture, Commodity, Home Use |

| Runner | Hot Runner |

| Design Software | UG |

| Installation | Fixed |

| Certification | CE, ISO |

| Standard | DME |

| Customized | Customized |

| After-sales Service | 5 Years |

| Injection Machine Size | 800tons |

| Mould Core and Cavity Metal | P20 |

| Mould Metal | P20 |

| Mould Name | Plastic Injection Adult Full Chair Molds |

| Transport Package | Wooden Case |

| Specification | big size |

| Trademark | prc mould |

| Origin | Huangyan Taizhou |

| HS Code | 8480719090 |

| Production Capacity | 350 Sets/ 1 Year |

Product Description

Customized injection plastic furniture chair table stool molds makingWe are offers customized plastic injection moulds according to customers' requests . Mainly including household mould, housewares mould, commodity mould, plastic furniture mould, chair mould, table mould, stool mould, crate mould, dustbin mould, pallet mould, flowerpot mould, laundry basket mould, painting bucket mould, drawer mould, basket mould, baby toys mould, trash can mould, basin mould, bucket mould, spoon mould, knife mould, fork mould, disposable box mould, thinwall box mould, cap mould etc.

Product Description

Big injection plastic chair mould, plastic chair mold, plastic injection chair mould making, plastic injection chair moulding, plastic injection chair molding, we made many plastic chair molds, such as home furniture chair mould, living room chair mold, hotel furniture mould, office furniture mould, adult chair mould, full chair mould, outdoor chair mould, armless chair mould, baby kids chair mould. How to make plastic chair? How to injection plastic chair molds ?

Advantages of our chair moulds:1: Specializing in the production of molds for adult armchairs, children's chairs, steel pipe chairs, and armless chairs.2: High quality plastic chair mold with competitive price. 3: We have experienced chair mold designers and skilled mold engineers. 4: Use excellent processing equipment. 5: Good mold stability and long mold life.6: Short cycle times for chair mold production.In the mold design of the plastic chair:1: We will fully analyze the chair according to the principles of injection molding (such as deformation, shrinkage, etc.).2: We will have serious and effective communication with mold buyers, including details such as weight, style design, size and appearance, stability and wear resistance of plastic chairs.3: We will refer to the previous chair injection mold design experience to improve the mold design.

| Injection Mould Name | Plastic adult full chair mould | ||||||||

| Mould Core and Cavity Metal | P20 | ||||||||

| Metal Hardness | HRC 28-32 | ||||||||

| Mould Base | Self-Made LKM DME | ||||||||

| Mould Runner | Cold Runner&Hot Runner | ||||||||

| Runner Brand | Yudo and Local Brand | ||||||||

| Cavity Number | 1 Cavity | ||||||||

| Cycle Time | 70 Seconds | ||||||||

| Tooling Lead Time | 90 Days | ||||||||

| Mould Life | 50-500 million shots/5-6years,even in 10 years in good maintenance | ||||||||

| Mould Precision | +/-0.01mm | ||||||||

| Gate Type | Pin Point Gate,Edge Gate,Sub Gate,Valve Gate,etc | ||||||||

| Mould Surface Treatment | EDM ,Texture,Mirror Polishing | ||||||||

| Mold Cooling System | Water Cooling,Beryllium Bronze Cooling ,etc | ||||||||

| Mould Hot Treatment | Quencher Nitridation ,Tempering,etc | ||||||||

| Our Advantage | Free Product 3D Design and Mould Structure Design | ||||||||

| Strict Quality Control | |||||||||

| Reasonable Price&Good After-Sales Service | |||||||||

| On Time Delivery | |||||||||

| Free Parts | |||||||||

| The main mold steel and hardness for your reference: | |||||||||

| Steel Grade | S50c | P20 | P20H | 718h | Nak80 | 2738H | H13 | 2344 | S136 |

| Hardness (HRC) | 17-22 | 28-32 | 33-37 | 33-38 | 34-40 | 36-40 | 48-50 | 48-52 | 48-52 |

Other Moulds

View more plastic injection moulds,you can click pictures.

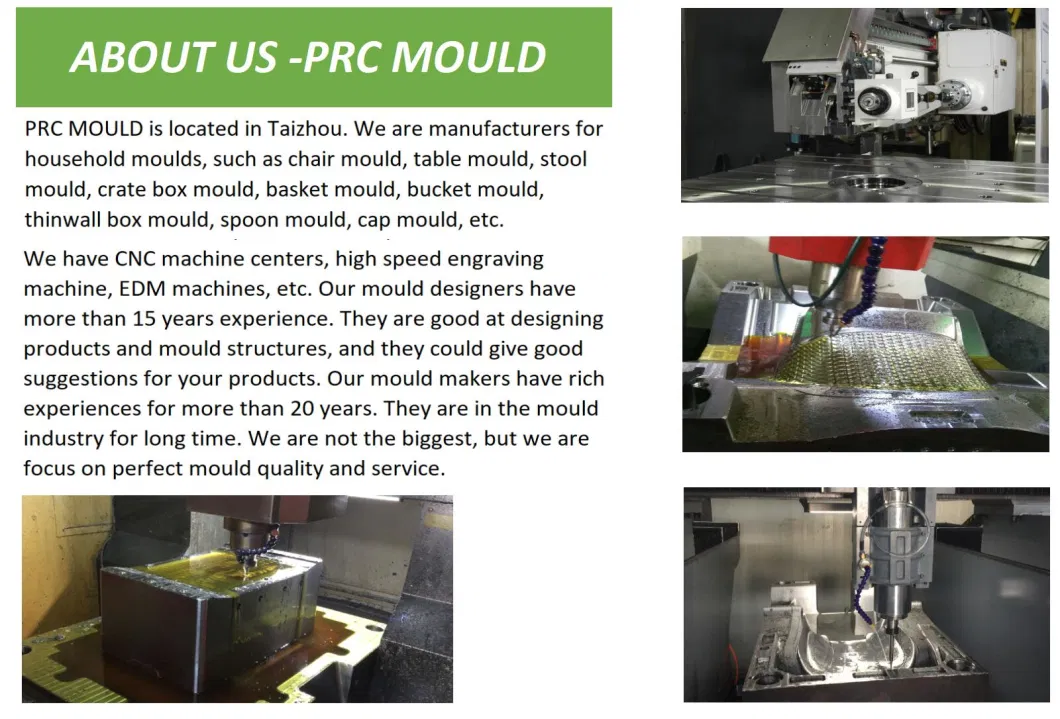

Company Profile

Why choose us

Production processing

How to do Injection mould/mold order processing :1 Design: according to plastic samples/ 3d drawing,it is free .2 Discussion: mould metal,cavity number,runner,payment method.3 Design mould: we will send drawing to you, you can check and confirm.4 Mould machine tooling: we will send machine working photos every week.5 Mould testing: we will send mould testing video and samples to you.6 Shipping : after confirm samples,we will shipping molds.

FAQ

PRC Mould always think more for clients , it is about saving time and money. We are looking forward to working with you.We provide good after-sales service, your satisfaction is our goal.We are not the biggest, but we are responsible and care about every mould quality for long-term business.Let us win to win together.Welcome to send us mould inquiry.